Keygen Cnc Simulator Pro

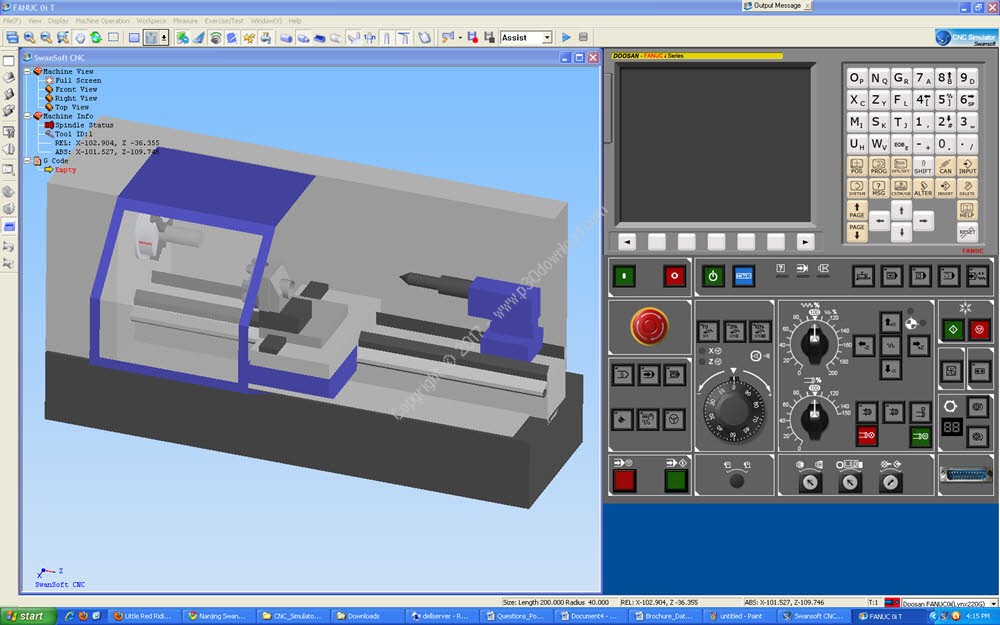

ScreenShots: Software Description: Swansoft CNC Simulator v7.2.2.0 Crack Swansoft CNC Simulator is real-time 3D CNCmachine system simulation and advanced G-code.

ScreenShots: Software Description: Swansoft CNC Simulator v7.2.2.0 Crack Swansoft CNC Simulator is real-time 3D CNCmachine system simulation and advanced G-code verificationsoftware. It allows the user to simulate all the CNC machineoperations and debug NC code using the same platform! 2D and 3D simulation – SSCNC is a real time 3D CNC simulator that uses OpenGL for fastand accurate 3D rendering modeling.

Zayde Dark Havana - opticianstore.ro. Capes by Sheena - livebusinessworld.com. Vgradnja oken in vrat, ki jih ponavadi tesnimo glede na smernice ral.Tukaj se najbolje obnesejo fiksna okna. Pri klasični gradnji, kjer zidamo z opeko, je zaradi nehomogenosti opeke oz. Lukenj v njej, po katerih se zrak hitro prenese po celotnem zidu in najde pot ven, je potrebno vse kanale, ki jih naredimo za inštalacije, predhodno ometati. Finished the laser cutter project! There are still a few things to add, like the exhaust blower, and air assist. Thanks to David and Greg for help on this project. Dogovor opcion a na pokupku doli v ooo obrazec. No Malware Detected By Free Online Website Scan On This Website. A free external scan did not find malicious activity on your website. If you still think that your website is infe.

– Dynamic rotation, zoom, pan, full screen and switch views duringsimulation in real time. – Realistic control panels and operator panels. – Realistic three-dimensional numerical control machine tools andcontrol panel.

– Cutter trace simulation. – Supports multiple monitors. – Total machining process simulation: selecting the workpiece,zeroing the workpiece, select and measure tools, select the rightoperation mode for the machine and clearing all the alarms.

– Machine simulation includes real components like coolant, soundfor machining operations and chips generation. – Workpiece setting and mounting. Allows to setup zeros and tooloffsets and the use of different clamping devices. – Three-dimensional measuring of workpiece after it ismachined. – Roughness measurements based on tool cutting parameters. – Materials library, edit and insert new materials.

– Database management tools and tools customization. – The turret can be configured for 4, 8 or 12 stations (front orrear). The automatic tool changer for the machining center can besetup horizontally or vertically. – Use virtual measuring tools: edge finder, feeler gauge,micrometer, calipers etc. – Windows MACRO recording and playback system. – Operation process recording and replay in AVI format. Program Editing – Programs are easily created in ASCII format using any texteditor.

– Edition capabilities (cut, copy, paste). – Numbering and renumbering of lines. – Changes in the lines of program are simple and intuitive.

– Help on screen for G/M codes. Swf to mp4 converter for mac. – Program verification of canned cycles and language syntaxaccording to the command code for the specific model. Advanced programming functions – G Code parser. Support ISO-1056 preparatory function codes (Gcodes), assistant function codes (M codes). – G-code debugging tool.

– Capability to simulate canned cycles, macros and the inclusion ofparameters. – FANUC, SIEMENS polar coordinate programming, G02, G03 spiralinterpolation.

– Support for custom code and cycles in different NC systems. – Simulates post processed files produced by UGS, Pro-E, MasterCAM. Operation of CNC machine – Preset zero point G54, G55, G56, G57 etc – Preset tool axes X and Z (Lathe) and height of tool(Milling). – Electronic hand wheel available.